Overview

Leaking Lift Pits and construction joints can be repaired using a range of products, the problem is most have fixings in the wall which can result in water ingress even after coatings have been applied.

The application of structural water proofing coatings and migratory water proofing chemicals can be very successful and are often tried in the first instance. If this is not fully successful there are options such as Structural water proofing resin injection, using single component or twin component systems. These are very costly and are very often only used where other methods have failed. As they are often integral to the structure, resin injection can stop running water under pressures far above the pressure resistance of standard water stop cement products used in surface application.

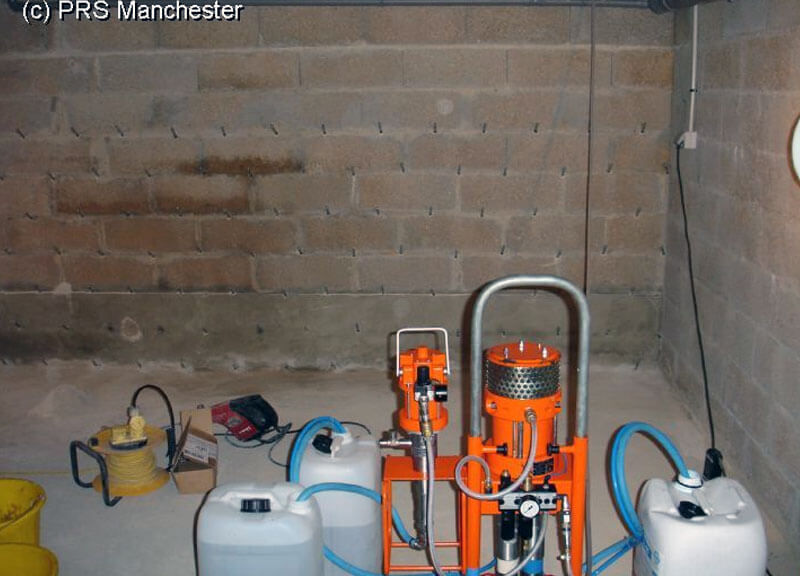

Professional Remedial Services have a range of products to suit all these types of situation, our expertise has resulted in many successful structural water proofing of Lift pits, LV pits, failed construction joints and even curtain injection structural waterproofing to stop walls leaking.

The Problem Wall requiring Structural Waterproofing

The Preparation for Structural Waterproofing

The Solution for Structural waterproofing

The Finished Wall

The Equipment